Steel rods – they are all around us, hidden in plain sight, supporting our roads, bridges and buildings.

While the metal is robust and versatile, its susceptibility to corrosion when used within concrete structures in aggressive environments costs the Australian economy billions each year. But what if we had access to a material twice as strong and corrosion resistant?

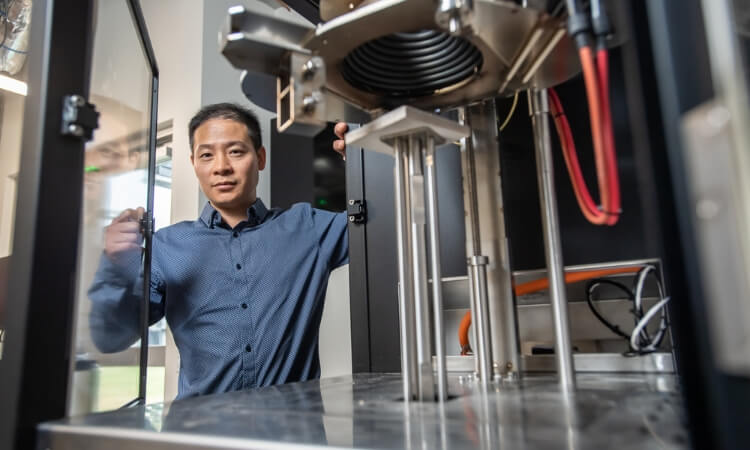

This is precisely what University of Southern Queensland researchers Professor Allan Manalo and Dr Omar Alajarmeh aim to achieve, as they join a national team helping to advance the country’s sovereign composites manufacturing industry.

In collaboration with Sustainable Construction Systems (Inconmat), UniSQ has been awarded more than $1 million from an Australian Government cooperative research centre project (CRC-P) grant to help develop and manufacture steel substitutes made from renewable glycerol-based resin systems (bio-resins), recycled glass and plastics.

“Our national construction industry uses around one billion meters of steel reinforcing a year,” Prof Manalo said.

“There are several alternative reinforcement materials available overseas but import times and shipping expenses make them costly.

“They are also manufactured using expensive thermoset resin systems and use natural sand for surface coating.”

Professor Manalo said combining glass fibres with polymer resins resulted in a material with twice the strength of steel and a lifespan of over 100 years, known as glass fibre reinforced polymer (GFRP) bars.

As part of the project, the team plans to investigate different formulas to develop novel GFRP bars. This includes the use of bio-resins and thermoplastics as a replacement for expensive resin systems and incorporating waste plastics and glass, to produce a cost-effective alternative to steel bars.

They will test the new materials’ properties at UniSQ’s state-of-the-art facilities and help facilitate commercial production of the new reinforcing technology at Inconmat’s manufacturing facilities.

The team will also focus on increasing Australia’s GRFP manufacturing efficiency and the creation of training and technology workshops to upskill industry leaders on the production of resilient infrastructure.

“Queensland’s Department of Transport and Main Roads is one of the project’s many industry partners,” Prof Manalo said.

“They will help develop business cases for the use of this material in future infrastructure projects.

“Also, with the Olympics coming to Brisbane in 2032, there will be new infrastructure investments required.

“If we can utilise the new reinforcement materials we can eliminate the need for maintenance and future proof these structures.”